The Handling Materials and Application of Impact Crusher:

This series impact crusher is able to crush coarse, medium and fine materials such as granite, limestone and concrete whose feeding granularity does not exceed 500mm and compression strength does not exceed 350MPa in many industries such asore crushing, railway, highway, energy, cement, chemistry and constriction. The size of the discharging granularity is adjustable, and the crushing specifications are diverse.

The Performance Characteristics of Impact Crusher:

This series impact crusher is able to process the materials whose length of a side is below 100~500mm and maximum compression strength is 350Mpa, and it has the advantages of big crushing chamber and that the crushed materials are in the form of cube, so that it is suitable for crushing medium hard materials such as limestone in cement plant, and it has such advantages as big production ability and small discharging granularity.

Features

1. It has big feeding mouth, high crushing chamber, high adaptability of the material hardness and small amount of stone powders

2. The gap between the impacting plate and the plate hammer is convenient to adjust so that it can effectively control the discharging granularity and the particle shape is good.

3. It has compact structure and strong rigidness, and the rotor has big rotational inertia.

4. It adopts high chromium plate so that it has shock resistance, abrasion resistance and big impacting force.

5. It adopts no key links so that it is convenient in maintenance and repair and economical and reliable.

6. It has comprehensive crushing functions, high production ratio, small abrasion and high comprehensive benefits.

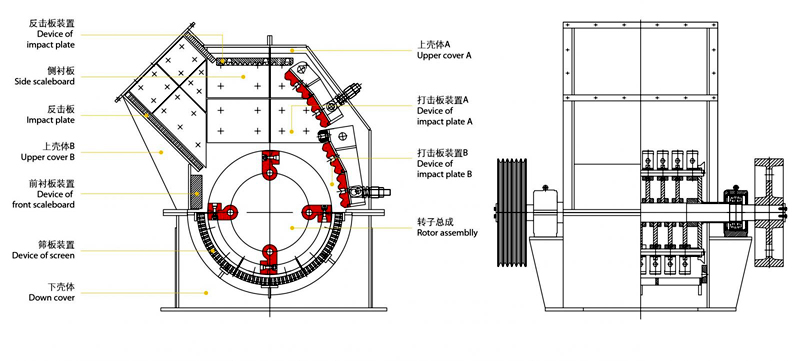

Working Principle

Impact crusher is a kind of crushing machine that uses impacting energy to crush materials. When the machine works, driven by the electro motor, the rotor will rotate with high speed, and when the materials go into the action zone of the plate hammer, they will strike and are crushed on the plate of the rotor, and then are crushed again when they are thrown to the impacting device, and then the materials will bounce back from the impact lining board and go to the action zone of the plate hammer and are crushed again. This process will proceed repeatedly, and the materials go into the first, second and third impacting chamber to be crushed until they are crushed to the required granularity, and then discharged from the discharging mouth. Adjusting the gap between the impacting rack and the rotor can change the discharging granularity and the shape of the materials.

Technological Data

|

Model

|

Specifications

(mm)

|

Feed opening

(mm)

|

Max.feeding side length

(mm)

|

Capacity

(t/h)

|

Power

(kw)

|

Total weight

(t)

|

Dimensions

( L×W×H)

(mm)

|

|

PF-1007

|

Φ1000×700

|

400×730

|

300

|

30-70

|

45

|

12

|

2330×1660×2300

|

|

PF-1010

|

Φ1000×1050

|

400×1080

|

350

|

50-90

|

55

|

15

|

2370×1700×2390

|

|

PF-1210

|

Φ1250×1050

|

400×1080

|

350

|

70-130

|

110

|

17.7

|

2680×2160×2800

|

|

PF-1214

|

Φ1250×1400

|

400×1430

|

350

|

100-180

|

132

|

22.4

|

2650×2460×2800

|

|

PF-1315

|

Φ1320×1500

|

860×1520

|

500

|

130-250

|

220

|

27

|

3180×2720×2620

|

|

PF-1520

|

Φ1500×2000

|

830×2040

|

700

|

300-550

|

400

|

50.6

|

3959×3564×3330

|