PRODUCTION DESCRIPTION

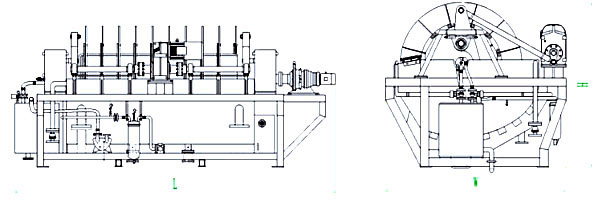

Disc vacuum filter — Product feature

Transmission devices have the following features: compact structure, reliable work, stepless speed regulation, change spindle speed according to different needs.

Disc vacuum filter — Product application

It can be used for floating and dewatering in clean coal and fine materials like tailings, and it can be also used in metallurgy, chemical, petroleum, sewage treatment, and other aspects of the solid-liquid

separation.

Disc vacuum filter — Product principle

Filter plate immersed in the pulp while in operation produces a surface absorption of filter cake, with the action of capillarity and integrated with vacuum pressure. Filtrate enters distributing valve and drainage tank through filter plate. Filter cake comes out from slime hopper receiving spray washing. Continuous dehydration for filter cake is conducted with the action of high vacuum force. Scraper will automatically discharge materials once entering the vacuum-free condition. filter cake falls into the tank by the pressure from the wind and scraper.

Disc vacuum filter — Technology parameter

|

model

|

Filtering area

(m2)

|

Number of filtering discs

|

Diameter of filtering discs

(mm)

|

Rotating of filtering discs

(r.p.m)

|

power of the main drive motor

(kw)

|

Power of the motor for agitating

(kw)

|

External dimensions

(L×W×H)

(mm)

|

weight

(kg)

|

|

PG9-2

|

9

|

2

|

1800

|

0.08~1.89

|

1.1

|

1.1

|

2290×2510×2100

|

2510

|

|

PG18-4

|

18

|

4

|

0.254~1.14

|

1.5

|

2833×2340×2295

|

3980

|

|

PG27-6

|

27

|

6

|

0.254~1.14

|

3820×2300×2320

|

4620

|

|

PG39-4

|

39

|

4

|

2700

|

0.074~0.72

|

1.5

|

3015×3275×3275

|

5650

|

|

PG58-6

|

58

|

6

|

0.254~1.14

|

2.2

|

2.2

|

3930×3355×3275

|

10980

|

|

PG78-8

|

78

|

8

|

0.254~1.14

|

4700×3400×3300

|

1360

|

|

PG116-12

|

116

|

12

|

0.285~1.285

|

4

|

4

|

6330×3355×3275

|

1500

|