It has the following features: stable performance, high automation, safe and reliable, easy to operate, backwashing can be realized

Filter press — Product application

Chamber filter press

It is suitable for concentrate filtration and dry discharge of tailings, the particle size can be up to 500 meshes.

Filter press — Product principle

Chamber filter press

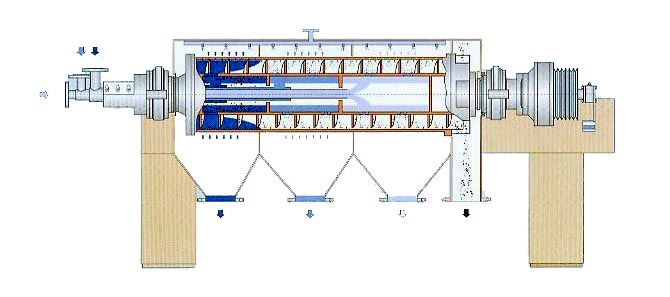

Working principle: chamber filter press takes filter cloth as the medium to separate solid and liquid. It is a separating machine with wide rang of particle size. The filter cloth spreads in a filter board surface, it is supported by the swelling groove of filter board, when the filter board is clamped, filter cloth turns to sealing materials, and the cavity between every two filter board forms a separated filter room. During the filter processing, the materials come through the central opening into filter room, the filtrate flow by the feeding pressure, flow out of the filter board after converged. Chamber filter press can be divided into two types according to filtrate discharging ways: open channel flow and under channel flow.

Plate and frame filter

Working principle: plate and frame filter separates solid from the liquid in filter form. It is a separating machine with wide rang of particle size. Materials come through the filter room that made up of filter board and filter frame,under the pressure of feeding materials, the filtrate flow through the medium that made up of filter board and filter frame-fiber gap of the filter cloth, arriving at the pattern surface, flow out of the filter board after converged. The solid that left in the filter frame forms filter cake. Plate and frame filter can be divided into two types according to filtrate discharging ways: open channel flow and under channel flow.

Filter press — Technology parameter

|

model

|

Filtering area

(㎡)

|

Number of the filter cells

|

Specifications of the filter box

|

Filtering sample thickness

(mm)

|

Filter cell volume

(m³)

|

Filtration pressure

(Mpa)

|

Anchor center

(mm)

|

External dimensions

(L×W×H)

(mm)

|

Motor power

(kw)

|

weight

(kg)

|

|

XM/AZ800U

|

20

|

20

|

800×800×55

|

25

|

0.239

|

0.5

|

2265

|

3215×1320×1160

|

2.2

|

2073

|

|

XM/AZ800U

|

30

|

30

|

0.365

|

0.8

|

2815

|

3765×1320×1160

|

3090

|

|

XM/AZ800U

|

40

|

40

|

0.491

|

0.8

|

3365

|

4315×1320×1160

|

3380

|

|

XM/AZ800U

|

50

|

50

|

0.617

|

1

|

3915

|

4865×1320×1160

|

3090

|

|

XM/AZ800U

|

60

|

60

|

0.743

|

4465

|

5415×1320×1160

|

4070

|

|

XM/AZ800U

|

70

|

70

|

0.869

|

1.6

|

5015

|

5965×1320×1160

|

4360

|

|

XM/AZ800U

|

80

|

80

|

0.995

|

5565

|

6515×1320×1160

|

4700

|

|

XM/AZ1000U

|

100

|

62

|

1000×1000×60

|

30

|

1.48

|

0.5-1.6

|

5020

|

6110×1460×1360

|

3

|

6200

|

|

XM/AZ1000U

|

120

|

75

|

1.8

|

5800

|

6890×1460×1360

|

6710

|

|

XM/AZ1250U

|

150

|

58

|

1250×1250×65

|

2.26

|

5390

|

6920×1850×1620

|

11800

|

|

XM/AZ1250U

|

180

|

69

|

2.7

|

6100

|

7630×1850×1620

|

12700

|

|

XM/AZ1250U

|

200

|

79

|

3.02

|

6620

|

8150×1850×1620

|

13300

|

|

XM/AZ1250U

|

220

|

84

|

3.29

|

7080

|

8610×1850×1620

|

13900

|

|

XM/AZ1250U

|

250

|

95

|

3.73

|

7290

|

9320×1850×1620

|

14800

|

|

XM/AZ1500U

|

300

|

77

|

1500×1500×70

|

32

|

4.76

|

0.7-1.6

|

7450

|

9100×1960×1780

|

5.5

|

27000

|

|

XM/AZ1500U

|

320

|

83

|

5.14

|

7870

|

9520×1960×1780

|

27690

|

|

XM/AZ1500U

|

340

|

88

|

5.45

|

8220

|

9870×1960×1780

|

28380

|

|

XM/AZ1500U

|

350

|

90

|

1500×1500×70

|

5.58

|

8360

|

10010×1960×1780

|

28730

|

|

XM/AZ1500U

|

380

|

98

|

6.08

|

8920

|

10570×1960×1780

|

29760

|

|

XM/AZ1500U

|

400

|

103

|

6.39

|

9270

|

10920×1960×1780

|

30450

|

|

XM/AZ1500U

|

450

|

116

|

7.21

|

10180

|

11830×1960×1780

|

32170

|

|

XM/AZ1500U

|

500

|

128

|

7.96

|

11020

|

12670×1960×1780

|

33890

|