According to the actual needs of customer, on the basis of introducing and absorbing advanced technology at home and abroad, our company designs a modern high performance crusher, HJ series high efficiency jaw crusher. It is based on the design concept of high input - high output, integrating the characteristics of low power - high productivity. Practice has proved that HJ series jaw crusher, with its excellent performance, reliable quality and high cost-effective, has won the trust of customers around the world, being an ideal upgrade alternative of the traditional jaw crusher.

HJ series jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

Advantages

1.Better performance than old ones: according to an in-depth study, SBM optimized motion trail of the movable jaw and the cavity of the machine.

2.The weight of counterweight and the structure of the Jaw crusher are adjusted, the vibration of whole machine is greatly improved and the performance is also well improved.

3.Utilize new bolt system, operators can replace the toggle easily.

Features

1. High Performance. The model has a large output, by the optimization of the trajectory of movable jaw plate and the cavity, to determine the optimum engagement angle and stroke property values, so that the productivity of this model has risen considerably with the same power.

2. High stability. By the optimization of the whole structure and the counterweight section to determine the structure of flywheel and driving wheel and the weight of counterweight section, so its function of vibration has been greatly improved. Compared with the same unit jaw crusher, HJ series possess a greater stability.

3. High reliability. Heat-treated forged eccentric shaft, extra large bearings, “E” frame, labyrinth seals, etc, making equipment sturdy and durable, more reliable.

4. Easy maintenance and operation. Advanced side fender bolt system makes the replacing of the side shield more faster; reasonable machine structure makes it more convenient for discharge setting and replacement of toggle plate. All this can effectively shorten the operation and maintenance time

5. Wide application. HJ series jaw crusher has a compact structure, compared with the same unit jaw crusher, it possess a smaller footprint. So that it can play a greater role in the limited space to suit a variety of crushing process.

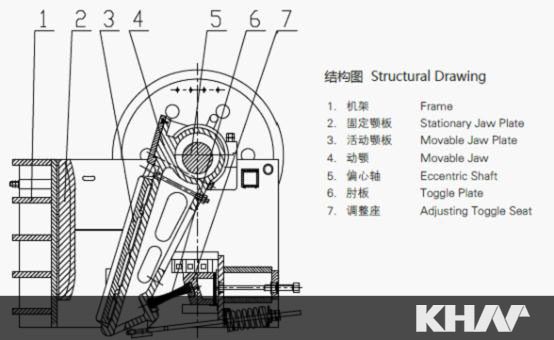

Working Principle

The working manner of this series crushing machine is dynamic extrusion type, and its working principle goes like this: the electro motor drives the belt and belt wheel to make the movable jaw to move up and down through the eccentric shaft, and then movable jaw goes up, the angle between the toggle pate and the movable jaw is bigger, thus pushing the movable jaw to get close to the fixed jaw, and at the same time, the materials are crushed or smashed, thus reaching the goal of crushing; when the movable jaw goes down, the angle between the toggle pate and the movable jaw is smaller, under the effect of the draw bar and the spring, the movable jaw moves always from the fixed jaw, and then the crushed materials will be discharged out from the lower mouth of the crushing chamber. With the continuous rotation of the electro motor, the movable jaw of the crusher will do periodic motion to crush and discharge the materials, thus realizing mass production.

Technological Data

|

Model |

Feed opening

(mm)

|

Max.feeding size

(mm)

|

Adjusting range of discharge opening (mm) |

Processing capacity

|

Motor power (kW)

|

Sides

(mm)

|

|

HJ98

|

650×980

|

560

|

75-175

|

110-350

|

90-110

|

2470×2000×2180

|

|

HJ110

|

800×1100

|

660

|

100-200

|

215-510

|

110-132

|

2875×2472×2530

|

|

HJ125

|

950×1250

|

800

|

125-225

|

280-650

|

132-160

|

3320×2600×3120

|